Baker Hughes Machine Design

- SECTOR Oil & Gas

- LOCATION Tulsa, OK

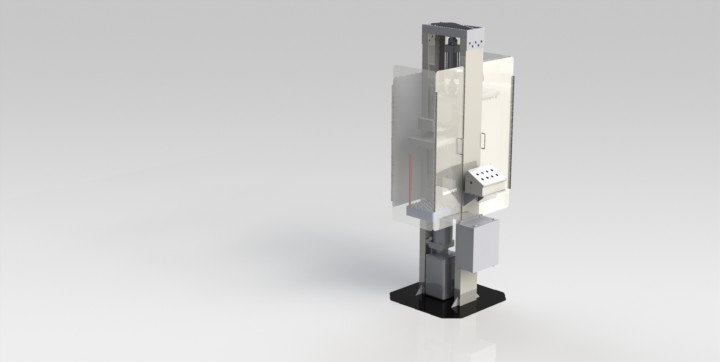

CENtrilift Design

Design and build of Heat Exchanger assembly machines.Baker Hughes was in need of a machine that would automate the assembly of heat exchanger tubes into plenums. They turned to AcerTech to take advantage of our experience and knowledge in mechanical design. Working closely with the client's specifications, our machine design team engineered an assembly machine that would include the installation of 20 heat exchanger tubes into plenums through one cycle of machine. Our engineering staff built and programmed the controls system and the unit was fully tested before delivery to the customer. With the implementation of the AcerTech designed machine, assembly of heat exchanger was reduced by more than 80%.

Project Features

- Plenum Engineering

- Control System Engineering

- 80% Assembly Time Reduction

- In-House Testing